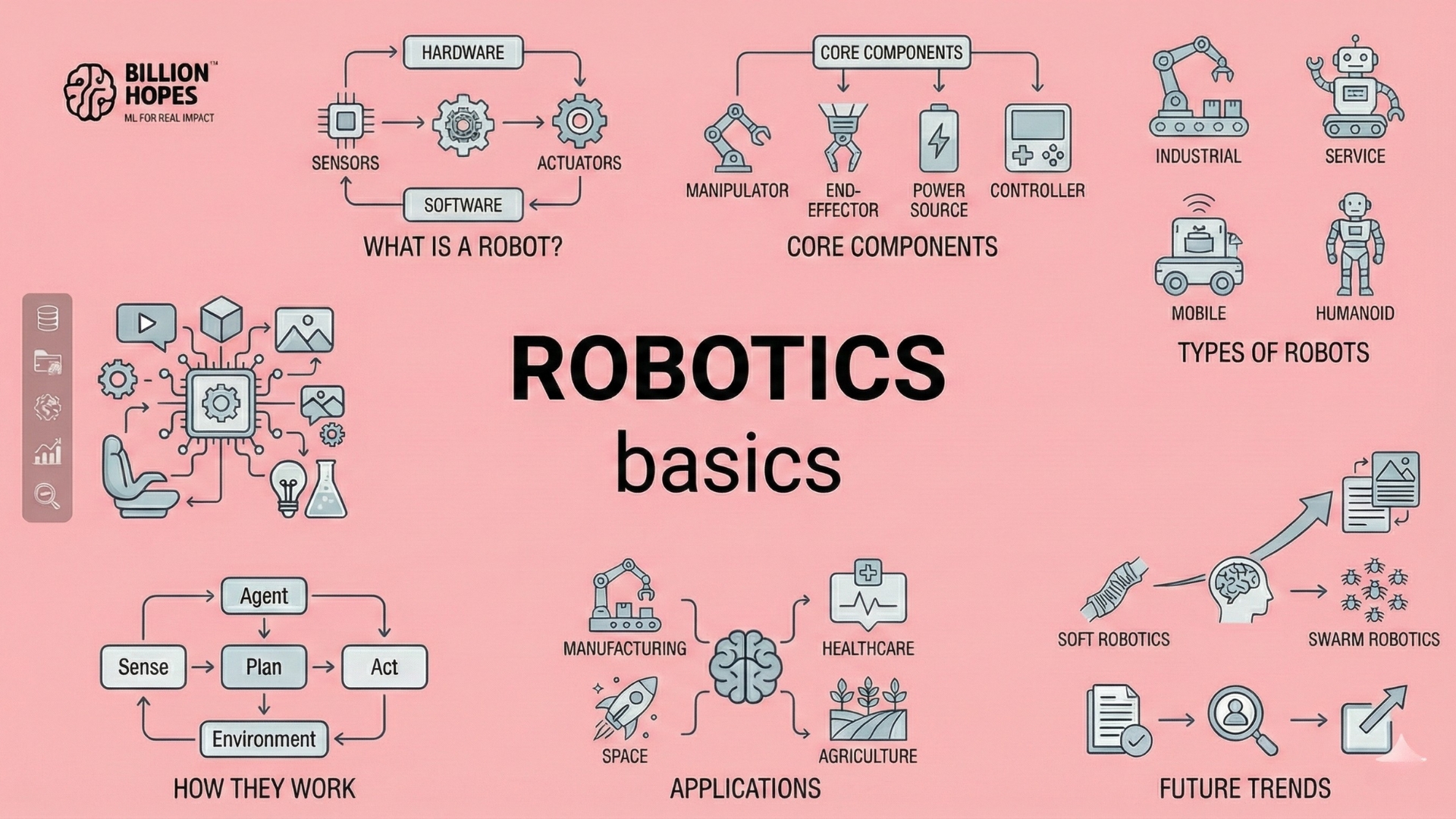

Robotics – basics

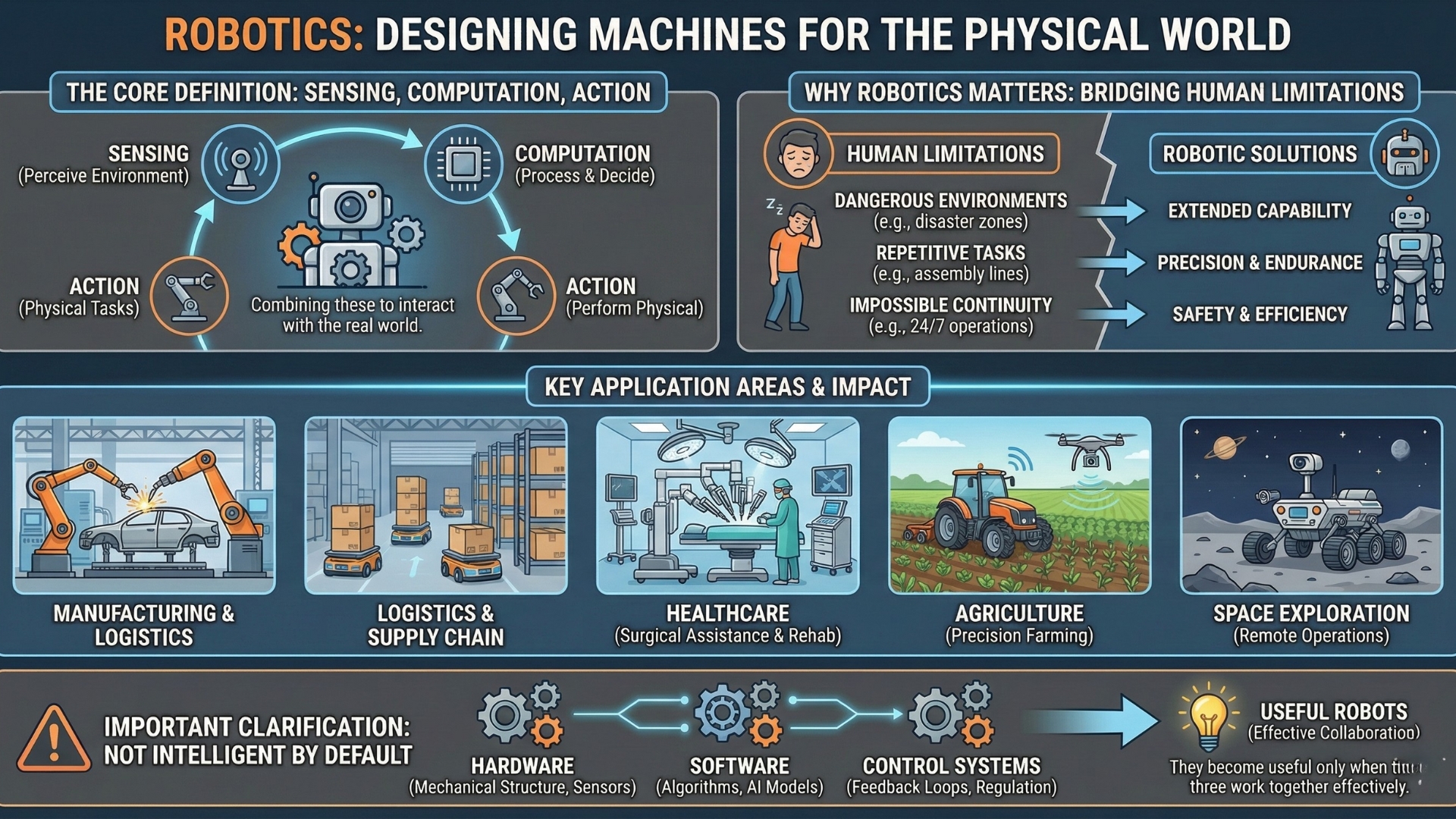

1. What is robotics and why it matters

Robotics is the field of designing, building, and operating machines that can perform physical tasks in the real world. These machines—robots—combine sensing, computation, and action to interact with their environment.

Robotics matters because the physical world still requires movement, manipulation, and precision. From manufacturing and logistics to healthcare, agriculture, and space exploration, robots extend human capability into environments that are dangerous, repetitive, or impossible for humans to operate in continuously.

Importantly, robots are not intelligent by default. They become useful only when hardware, software, and control systems work together effectively.

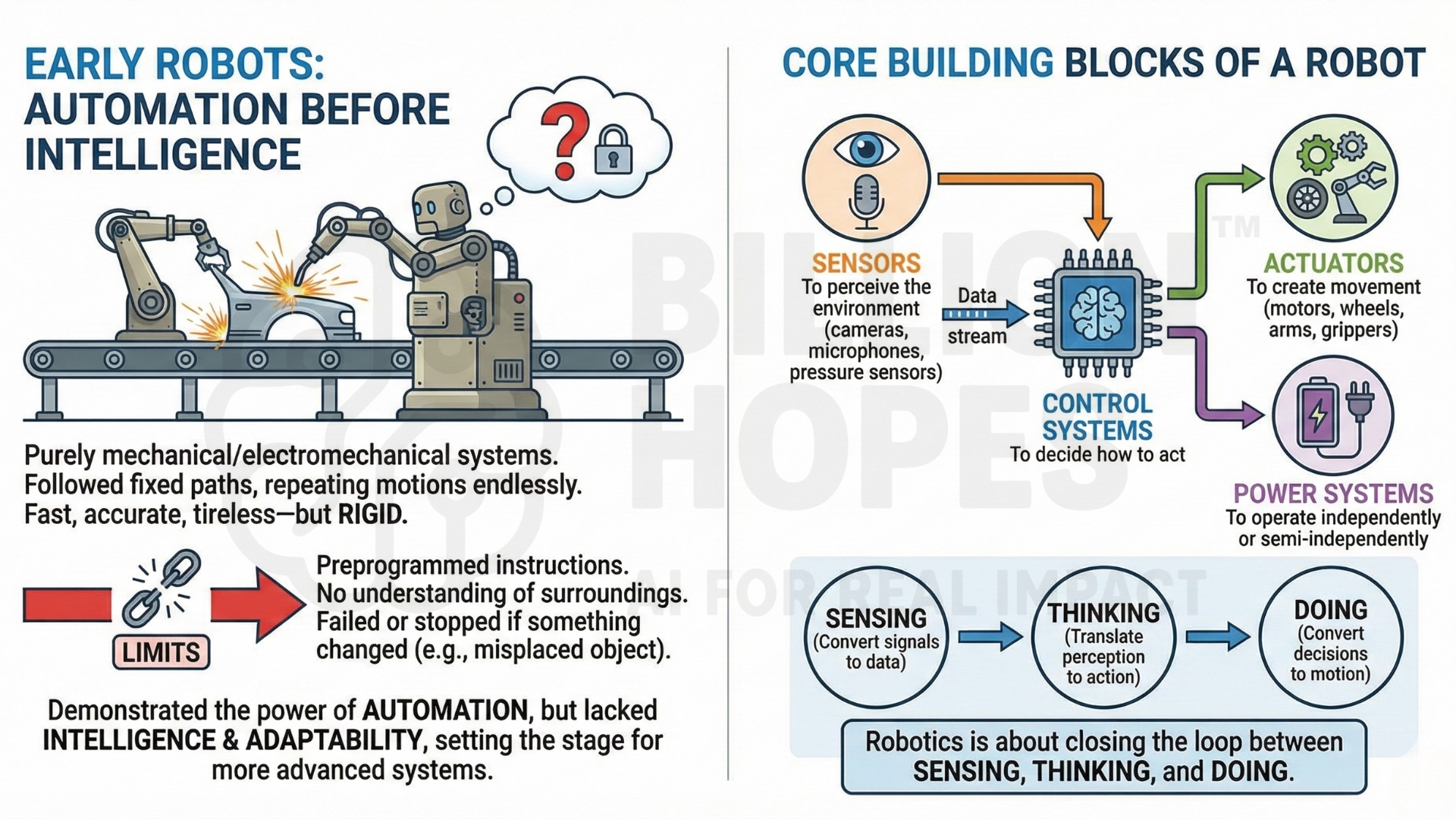

2. Early robots: Automation before intelligence

The earliest robots were purely mechanical or electromechanical systems. Industrial robots in factories followed fixed paths and repeated the same motions endlessly. They were fast, accurate, and tireless—but also rigid.

These systems relied on preprogrammed instructions with no understanding of their surroundings. If something changed—a misplaced object or a new obstacle—the robot failed or stopped entirely.

This era of robotics demonstrated the power of automation but also its limits. Intelligence and adaptability were missing, setting the stage for more advanced robotic systems. An excellent collection of learning videos awaits you on our Youtube channel.

3. Core building blocks of a robot

Every robot, regardless of complexity, is built from a few fundamental components:

- Sensors to perceive the environment (cameras, microphones, pressure sensors)

- Actuators to create movement (motors, wheels, arms, grippers)

- Control systems to decide how to act

- Power systems to operate independently or semi-independently

Sensors convert physical signals into data. Actuators convert decisions into motion. Control systems sit in between, translating perception into action.

Robotics is ultimately about closing the loop between sensing, thinking, and doing.

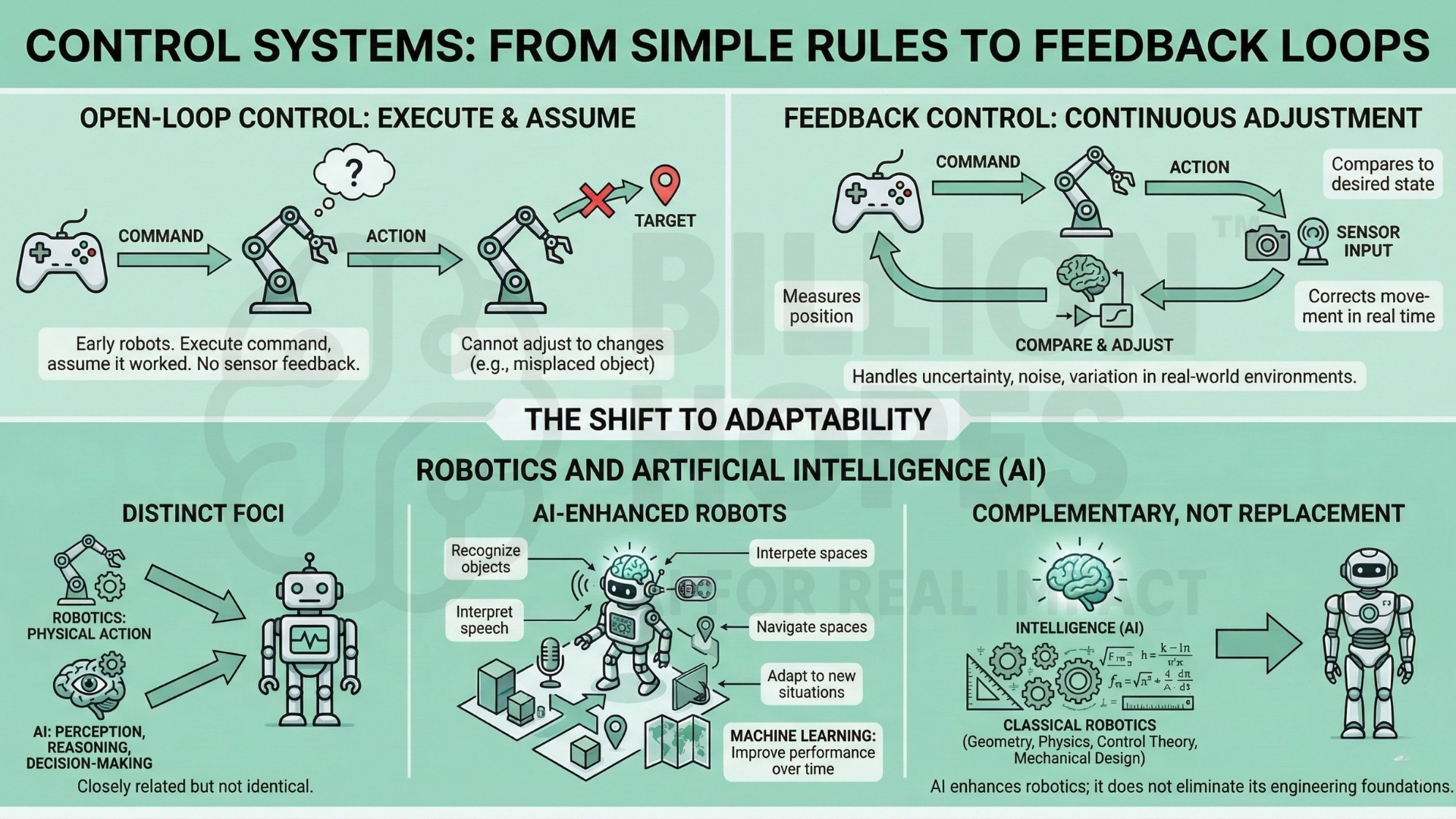

4. Control systems: From simple rules to feedback loops

Early robots used open-loop control: execute a command and assume it worked. Modern robots rely on feedback control, continuously adjusting actions based on sensor input.

For example, a robotic arm does not just move to a position once. It measures where it is, compares that to where it should be, and corrects its movement in real time.

This feedback-based approach allows robots to handle uncertainty, noise, and variation—essential in real-world environments where conditions are never perfect. A constantly updated Whatsapp channel awaits your participation.

5. Robotics and artificial intelligence

Robotics and AI are closely related but not identical. Robotics focuses on physical action; AI focuses on perception, reasoning, and decision-making.

When AI is added to robots, machines can recognize objects, interpret speech, navigate spaces, and adapt to new situations. Machine learning allows robots to improve performance over time rather than relying solely on fixed instructions.

However, AI does not replace classical robotics. Geometry, physics, control theory, and mechanical design remain essential. Intelligence enhances robotics—it does not eliminate its engineering foundations.

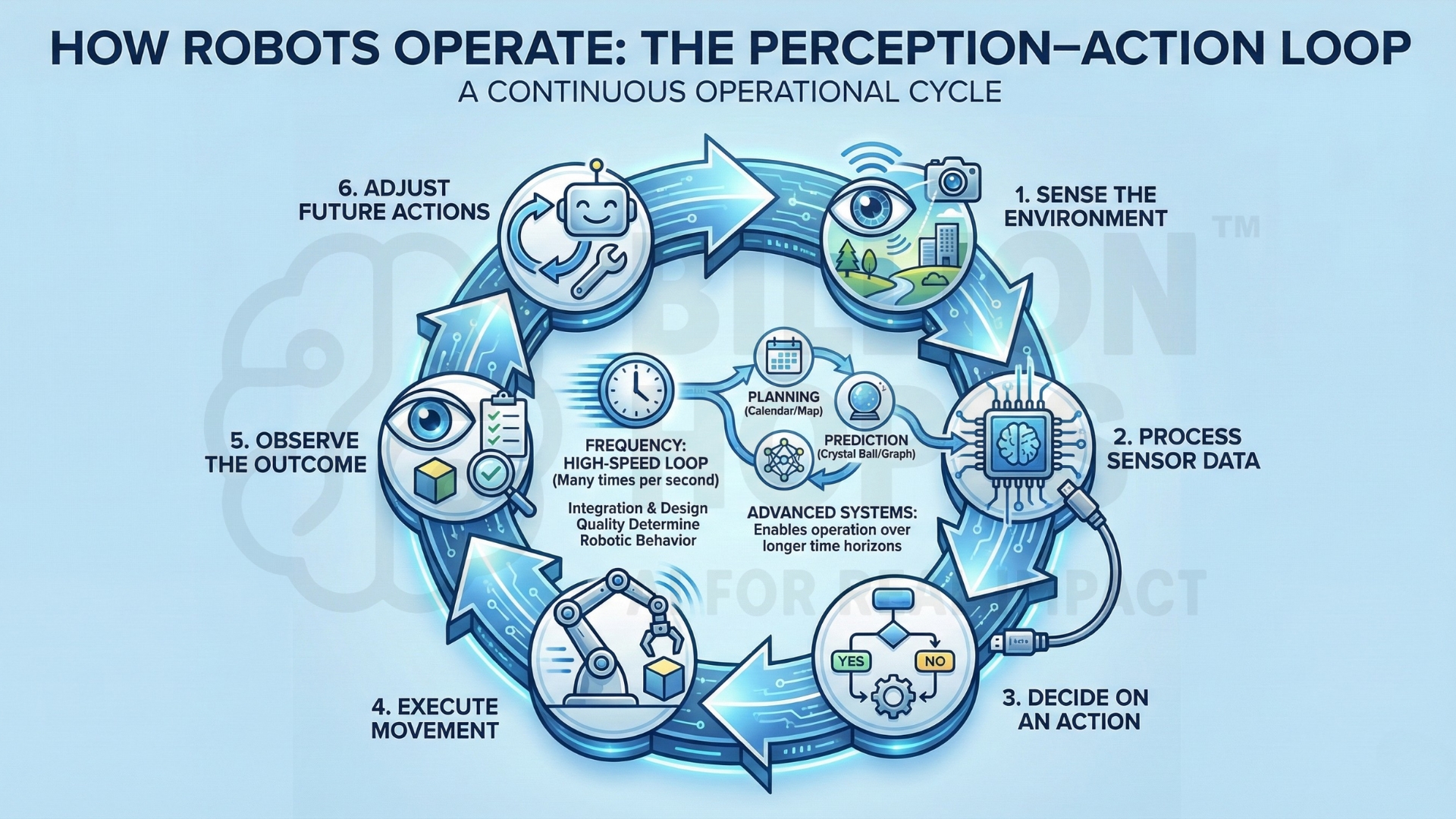

6. How robots operate: The perception–action loop

Most robots follow a continuous operational loop:

- Sense the environment

- Process sensor data

- Decide on an action

- Execute movement

- Observe the outcome

- Adjust future actions

This loop may run many times per second. The quality of robotic behaviour depends on how well each step is designed and integrated.

In advanced systems, this loop includes planning, prediction, and learning, enabling robots to operate over longer time horizons.

Excellent individualised mentoring programmes available.

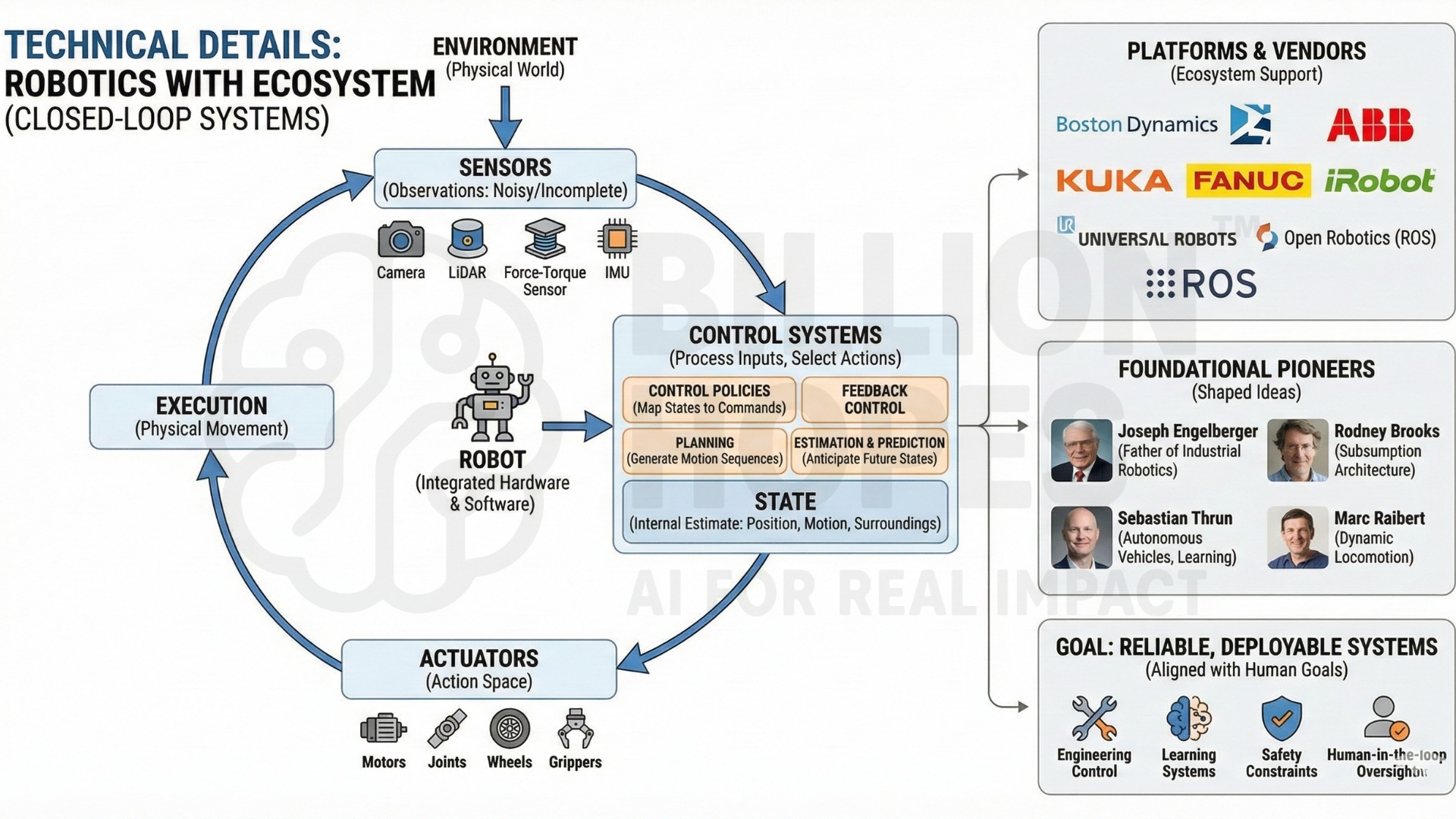

TECHNICAL DETAILS (Robotics with ecosystem): Robots are built from tightly integrated hardware and software components operating as closed-loop systems. The environment is the physical world in which the robot functions, while the state represents its internal estimate of position, motion, and surroundings. Sensors – such as cameras, LiDAR, force-torque sensors, and IMUs—provide observations that may be noisy or incomplete. Control systems process these inputs to select actions from an action space defined by actuators like motors, joints, wheels, and grippers. Control policies map sensed states to motor commands using feedback control. Planning generates motion sequences, while estimation and prediction anticipate future states. Execution converts commands into physical movement, and feedback continuously updates internal models. In modern robotics, these layers are supported by platforms and vendors such as Boston Dynamics, ABB, KUKA, Fanuc, iRobot, Universal Robots, and research-driven organizations like Open Robotics (creators of ROS). Foundational ideas in robotics were shaped by pioneers such as Joseph Engelberger (often called the father of industrial robotics), Rodney Brooks (subsumption architecture), Sebastian Thrun (autonomous vehicles and robotics learning), and Marc Raibert (dynamic locomotion). Together, engineering control, learning systems, safety constraints, and human-in-the-loop oversight turn raw machinery into reliable, deployable robotic systems aligned with human goals.

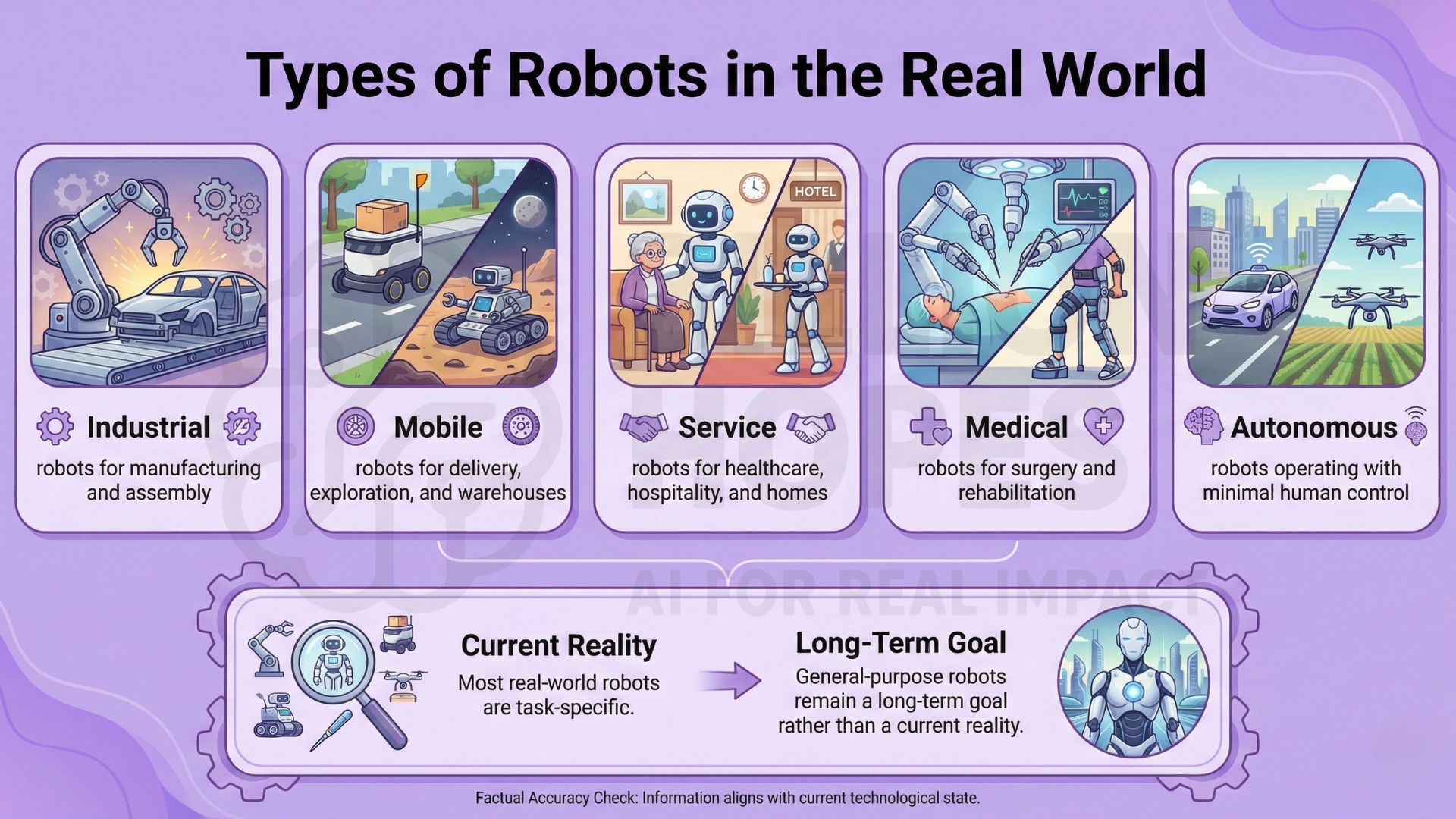

7. Types of robots in the real world

Robots appear in many forms:

- Industrial robots for manufacturing and assembly

- Mobile robots for delivery, exploration, and warehouses

- Service robots for healthcare, hospitality, and homes

- Medical robots for surgery and rehabilitation

- Autonomous robots operating with minimal human control

Most real-world robots are task-specific. General-purpose robots remain a long-term goal rather than a current reality.

8. Human-robot interaction

Robots rarely operate alone. Humans supervise, collaborate with, or control them. Designing safe and intuitive interaction is a major challenge in robotics.

Poorly designed robots can be dangerous, confusing, or inefficient. Effective systems use clear signals, constraints, and fallback mechanisms to ensure humans remain in control.

The future of robotics depends not only on better machines, but on better collaboration between humans and machines. Subscribe to our free AI newsletter now.

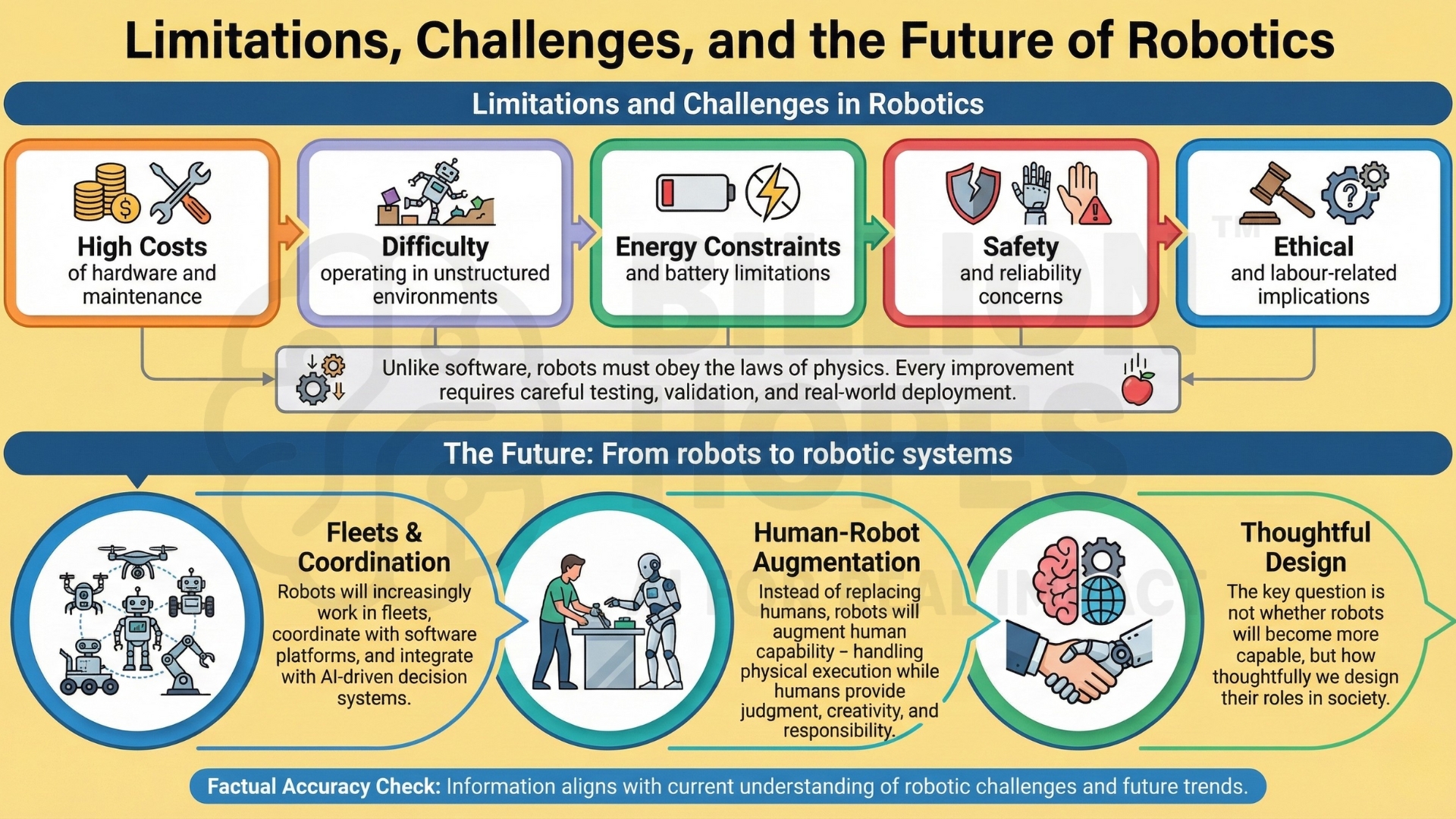

9. Limitations and challenges in robotics

Robotics faces persistent challenges:

- High costs of hardware and maintenance

- Difficulty operating in unstructured environments

- Energy constraints and battery limitations

- Safety and reliability concerns

- Ethical and labour-related implications

Unlike software, robots must obey the laws of physics. Every improvement requires careful testing, validation, and real-world deployment.

10. The future: From robots to robotic systems

The future of robotics lies in systems rather than individual machines. Robots will increasingly work in fleets, coordinate with software platforms, and integrate with AI-driven decision systems.

Instead of replacing humans, robots will augment human capability – handling physical execution while humans provide judgment, creativity, and responsibility.

The key question is not whether robots will become more capable, but how thoughtfully we design their roles in society. Upgrade your AI-readiness with our masterclass.

Summary

Robotics is the discipline of building machines that act in the physical world. Grounded in engineering, control theory, and increasingly AI, robots sense, decide, and move to perform useful tasks. While automation provides efficiency, intelligence adds adaptability. Understanding robotics basics is essential for navigating a future where humans and machines increasingly work side by side – not as rivals, but as collaborators.